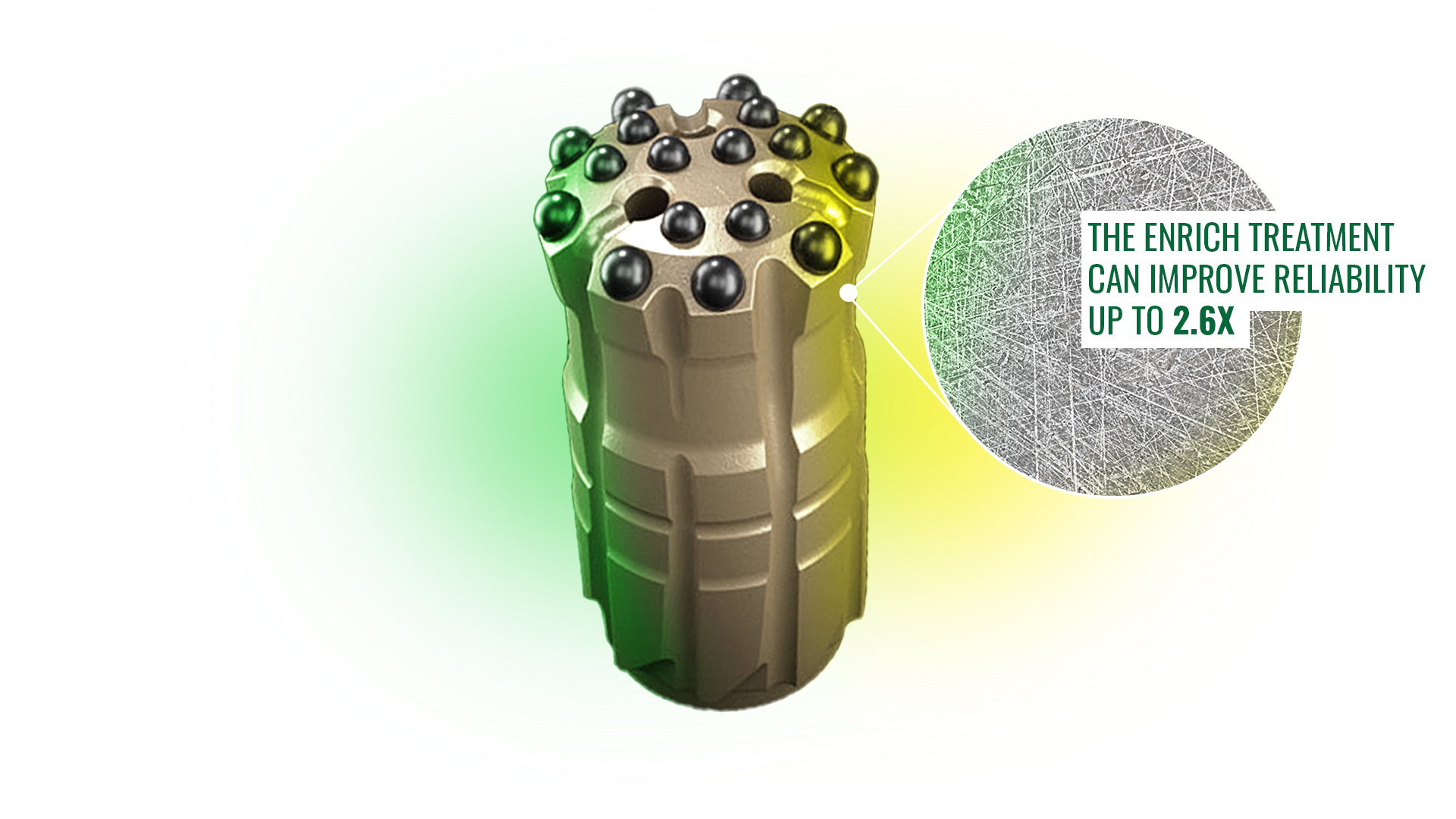

CRYSTAL STRUCTURE REALIGNMENT REPRESENTATION

ENRICH BITS & TOOLS: RELIABILITY RETURNS

re·li·a·bil·i·ty

/rəˌlīəˈbilədē/

noun

the quality of being trustworthy or of performing consistently well.

“the car’s background gives me every confidence in its reliability”

Similar: dependable, authentic, genuine, trustworthy, constant, loyal, dedicated, safe

re·turns

/rəˈtərns/

noun : profits from an investment.

“product areas are being developed to produce maximum returns”

Similar: yield, profit, gain, income, revenue, interest,

Enrich Bits & Tool

Provides advanced cryogenic treatments for tools to bring reliability back to your operations.

We are committed to optimizing drilling, extending equipment life cycles, cutting downtime, and reducing waste.

Why Should You Care?

Planned obsolescence has poisoned our market and productivity. “They don’t make things like they used to.” is a common saying because profits have taken over from the traditional idea of creating the best product on the market. The idea of making things last is disappearing and our goal is to hold to what we believe is the right thing to do. Treating materials to make them last longer saves the USER money, saves the ENVIRONMENT from wasted materials and energy, and saves the WORKER from unneeded downtime. If a replacement can be done once per year instead of multiple times, a large portion of the RISK IS ELIMINATED which is associated with the job hazard.

Schedule your treatment today

Don’t wait until your parts run out!

Email us at orders@enrichbits.com to schedule your treatment with Enrich Bits and Tools.

Frequently Asked Questions

Click to expand

Reduce the risk associated with maintenance by eliminating the replacement of worn parts. As equipment availability is increased, the need for maintenance manpower is reduced, transportation of new parts inside the pit is reduced, and months of lead time for replacement parts is eliminated. These factors impact production and your maintenance, repair, and overhead costs.

- Abrasive Wear Resistance

- Corrosion reduction

- Adhesion and fretting wear reduction

- Increased thermal dissipation

- Interior stress relief

For every 1 ton of steel made, it takes: 1.6 tonnes of iron .77 tonnes of coal. Manganese, nickel, chromium, molybdenum, boron, titanium, vanadium, tungsten, cobalt, and niobium. And 6,000 tonnes of fuel for the round trip to transport it across the ocean. Combining all the extraction for these raw materials, time, and resources so that a bit can last less than 2 holes in a granite quarry is a tremendous expense. Our process is the last step in creating a crucial difference in performance. Doubling the life of a single bit reduces the demand and your global impact. Report this on your Toxic Release Inventory.

Advanced cryogenics has been fine-tuned since 1877. Over the years countless improvements have been discovered because of the curiosity of people and the persistence of those who were told it could not be done. Notable applications such as space travel and turbojet engines have utilized similar technology. Creating a machine to scale to industrial-size clients and effectively cycle nitrogen was a challenge.

The Enrich Bits and Tools process is reserved for new parts only. Benefits are not observed if the part has already been damaged. Benefits have been observed in several materials and applications. An exact list of items can not be provided due to the large variety of metal producers globally. Each item is tested prior to treatment to determine if benefits will be observed.

The proprietary advanced cryogenic process utilizes nitrogen to bring the temperature of the materials down to temperatures that allow the crystal structure to realign. This highly controlled process reduces impurities from the material by altering the time and temperature curve, reducing the austenite remaining in the matrix, and completing the martensitic reaction. This treatment increases the wear properties ( such as abrasion, corrosion, and adhesive wear ) throughout the entirety of the item. This is not a surface coating like our competitors provide which loses benefits once the coating is worn off. Our treatment penetrates deeply into the entire part to ensure improved reliability in the field.

For Example:

Similar to the shock wave of explosives propagating through a rock mass, much of the energy is reflected back toward the source when the energy encounters bedding planes or voids. The same principles apply to vibrations through materials like metal of a bit during drilling. The vibrations inside the metal bounce back and forth through the material as it encounters the impurities. This retention of vibrations increases the heat of the material which then causes fatigue over time.

Enrich Bits and Tools aims to minimize the imperfections that cause fatigue on parts subjected to long-term wear.

No, this process is not like in the movies when you see a blacksmith quench a sword. The original principles hold true but advances in instrumentation and technology allow for a more controlled and successful process. More importantly, repeatable.

Yes, It will not wear off of the surface like a coating or paint. The treatment penetrates deep into the item to permanently strengthen the bonds of the existing item. This treatment is irreversible and can only be applied to new Bits and Tools. The only time the treatment can be reversed is when the tooling application is returned to red hot or molten temperatures. As you can understand, this will return the item to its original state prior to treatment. An example of this would be snow clearing at high speeds. Regular grader use and slow speeds maintain the benefits, but if a snow plow is operating on the highway, the part will lose its benefits at a higher rate.

As a value-added service, we can provide several options.

Included in the basic service, we always test tooling from a new supplier using an industry-standard measurement device to determine the elemental composition of the bits and tools sent.

Secondly, we can provide a batch test for the items every time we treat them. This ensures the manufacturer of the tooling is providing consistent materials.

Finally, we can record and report so you can manage the quality control of the parts you are receiving from your supplier. This is a value-added service for you to maintain Quality Assurance that the parts you are receiving are consistent from the manufacturer.

If the parts being treated contain a certain percentage of some elements, we know the treatment will not provide additional benefits to the item. We will not treat them and the items will be returned.

Contact us further for more information.

If you have a preferred shipping account, we can use your account. If we handle shipping, there is a surcharge to cover costs and the shipping will be added to your invoice.

info@enrichbits.com